|

|

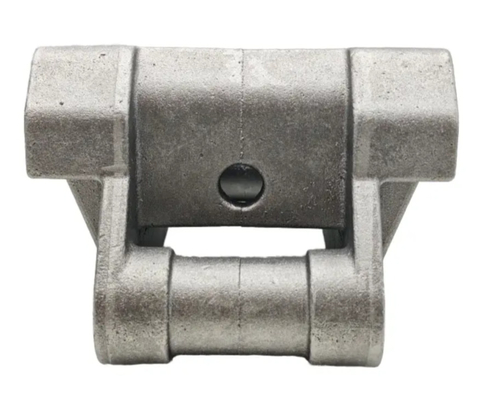

Ductile Iron Sand Casting Connection Seats Seeder Accessories

|

Product Details:

Payment & Shipping Terms:

|

Detailed Product Description

| Product Name: | Connection Seats | Material: | Ductile Iron |

|---|---|---|---|

| Process: | Sand Casting | Application: | Machinery Part |

| Size: | As Per Drawing | Finsh: | Sandblasting |

Ductile Iron Sand Casting Connection Seats Seeder Accessories

Product Details

Production Process

![]()

Quality Control

![]()

FAQ

1.Q: What should I offer to get the price?

A: Please provide us with your drawings (material, dimensions, surface treatment, tolerances or other technical requirements), quantities, applications or samples, and then we will provide you with a more accurate and reasonable price.

2.Q: What is your minimum order quantity?

A: We accept small orders, even sample orders.

3.Q: Are you a factory or a trading company?

A: We are a trading company, but with our own factory, we provide you with a one-stop service from mold design to finished parts.

4.Q: What is your delivery time?

A: It depends on your casting size, technical requirements and quantity, under normal circumstances, sample within 25 working days, mass production within 60 working days.

5.Q: What payment terms do you accept?

A: Wire transfer, letter of credit, paypal, Western Union, etc.

Contact Details

Sunrise Foundry CO.,LTD

Contact Person: Paul

Send your inquiry directly to us

More Ductile Cast Iron

-

Ductile Iron Sand Casting Valve Hardware Accessories

-

Ductile Cast Iron ASTM A536 65-45-12 Gear Housing for Industrial Applications

-

QT800-2 Ductile Iron Sand Casting Crankshafts for Auto Spare Parts

-

ASTM A536 65-45-12 Ductile Iron Sand Casting Parts

-

ASTM 60-40-18 Ductile Iron Resin Sand Casting

-

Ductile Iron Sand Casting Air Duct Cover