|

|

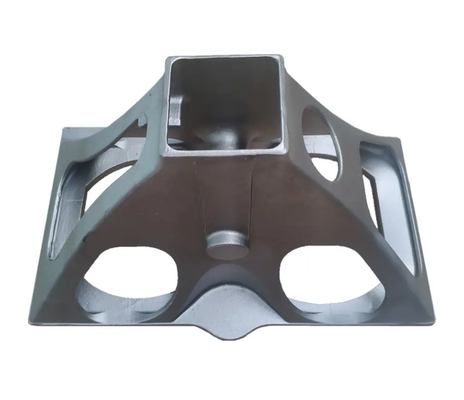

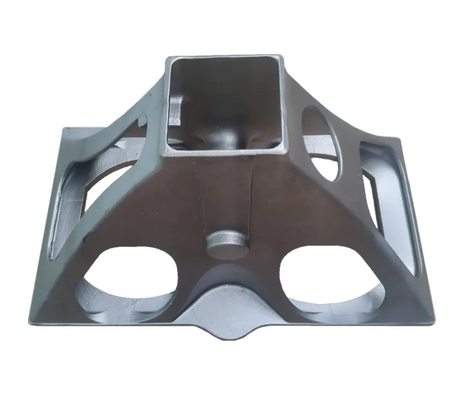

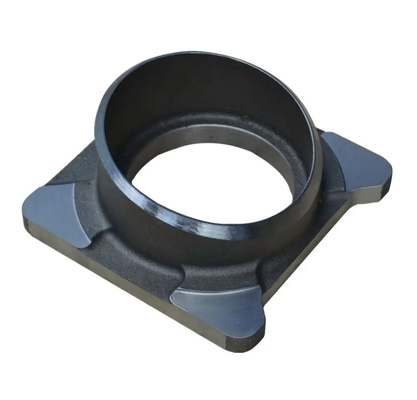

Stainless Steel Lost Wax Precision Casting Railway Parts

|

Product Details:

Payment & Shipping Terms:

|

| Material: | Stainless Steel | Application: | Railway |

|---|---|---|---|

| Process: | Precision Investment Casting | Finish: | Sand Blasting, Machining, Painting |

| Tolerance: | CT4-CT6 | OEM: | Available |

Stainless Steel Lost Wax Precision Casting Railway Parts

Product Details

Production Process

-Mold design

According to customers’ drawing, our engineer will finish the mold design.And then make the mould according to the design.

-Wax injection

The wax is being injected by the machine. Wax design of the desired castings is produced by injection molding.

-Assembly tree

-Shell making

The shell is built by immersing the assembly in a liquid ceramic slurry and then into a bed of extremely fine sand. Up to 6 layers may be applied in this manner. The shell will be dry in each layer making.

-Dewaxing

Once the ceramic is dry, then heating. The wax will be melted out. The melted wax will be flow out from the shell.

-Casting

In the conventional process, the shell is filled with molten metal by gravity pouring. As the metal cools, the parts and gates,

sprue, and pouring cup become solid casting.

-Knock-out

When the metal has cooled and solidified, the ceramic shell will be broken off by vibration or a knock-out machine.

-Cut off

The parts are cut away from the central spruce using a high-speed friction saw.

-Grinding

After the casting was cut off. The casting pouring part will be ground carefully.

-Inspection and post treatment

The casting will be inspected by the inspector as per the drawing and quality request. If there are unqualified parts. It will be repaired and inspected again.

-Finished casting

After surface finishing operations, the metal castings become identical to the original wax patterns.

-Machining

The casting blank will be machined by CNC according to customers’ drawings.

-Testing

The finished parts will be tested by the professional inspection engineer.

-Packing

The qualified parts will be packed according to customers’ request.

![]()

About Us

Sunrise Foundry is a professional Metal Foundry, located in Ningbo. We have been producing Gray Iron,

Ductile Iron Castings and and any other precision castings for more than 25 years.

We are dedicated to meet different requirements of various customers across the world, products are mainly

involved Agricultural and Construction Machinery, Hydraulic, Mining industry, Municipal Products, some steel

and stainless steel castings for Pumps and Valves, Pipe Fittings, etc.

Please feel free to contact us if you have any requests.

Quality Control

![]()

FAQ

Q: Are you a factory or trading company?

A:We're a direct factory,we have our own casting foundry and machining factory over 30 years.

Q: Do you make customized products based on our design drawings?

A: Yes, we are a professional metal fabrication factory with 20 experiences to make custom products according to clients' drawings.

Q: Will my drawing be safe after you get it?

A: Yes, we will not release your design to third party unless with your permission.

Q: What is the MOQ?

A: Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standard.

Contact Person: Paul

-

Kitchenware Parts Bathroom Hardware 304 316 Stainless Steel Casting Parts Lost Wax Casting

-

Stainless Steel Precision Investment Casting Farm Machinery Parts

-

Precision Investment Casting 304 316 Stainless Steel Lost Wax Casting Pump and Valve Parts

-

Lost Wax Casting 304 316 Stainless Steel Investment Casting Golf Head

-

304 316 Precision Investment Stainless Steel Casting Machinery Parts

-

304 316 Stainless Steel Lost Wax Casting Parts Machine Hardware Parts