|

|

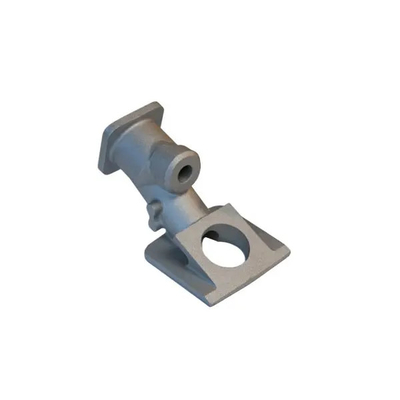

Investment Casting Steel Parts Mechanical Components

|

Product Details:

Payment & Shipping Terms:

|

| Material: | Steel | Process: | Investment Casting |

|---|---|---|---|

| Standards: | AISI,ATSM,UNI,BS,DIN,JIS,GB Etc. | Size: | As Customer's Drawings Or Samples |

| Finish: | Sandblasting | OEM: | Available |

Investment Casting Steel Parts Mechanical Components

Product Details

| Process | Investment casting Precision casting Lost wax casting |

| Processing Ability | Surface finishment: Ra1.6-Ra3.2 |

| Size tolerance: VDG P690 D2 | |

| Maximum size: ≤1200mm×800mm×400mm | |

| Weight range: 0.1Kg-120Kg | |

| Material |

stainless steel, carbon steel, alloy steel, heat-resistant steel, hardend steel,mild steel |

|

Brass CuZn38,H62 Aluminum bronze AB2,863 |

|

| Cast aluminium alloy ZL101,ZL114A,A356 | |

| Application |

Mechanical Components/parts Boat parts and Marine hardware Construction hardware Auto parts and accessories Medical Instrument parts pump & valve parts and accessories Impellers and propellers(propellors) Pipe Fittings or pipeline accessories Other industry metal casting parts |

| Design | Various type of 2D or 3D drawings are acceptable,such as JPG,PDF,DWG,DXF,IGS,STP,X_T,SLDPRT etc. |

| Standards | AISI,ATSM,UNI,BS,DIN,JIS,GB etc. |

| Inspection |

Dimension inspection Chemical composition analysis (Spectrum analysis) Mechanical property testing X-Ray inspection Dye penetrant inspection Magnetic powder inspection Metallographic inspections |

Production Process

![]()

Quality Control

![]()

FAQ

Service/Management of your factory?

A: We supply ODM & OEM services with strong R&D team and QC system.

What materials can you produce?

A: stainless steel; Carbon Steel; Alloy Steel

We test every furnace chemical component before pouring by spectrometer.

What information should I let you know if I want to get a precise quotation?

A: Please kindly send me your drawings. 2D in PDF or DWG format, 3D in STEP or IGS format.

How long get my customized sample?

A: Usually 25-30days. Including open moulds and develop samples time.

Contact Person: Paul

-

Cast Steel Railroad Accessories and Machine Parts Casting

-

Cast Steel Engine Block for Auto Spare Parts

-

Precision Investmet Casting Steel Bearing Block Seat

-

Precision Steel Investment Casting Construction Machinery Metal Fittings

-

Precision Coal Steam Investment Castings Boiler Parts Air Nozzle Hood Boiler Spare Parts

-

Excavator Precision Investment Steel Casting Track Roller