|

|

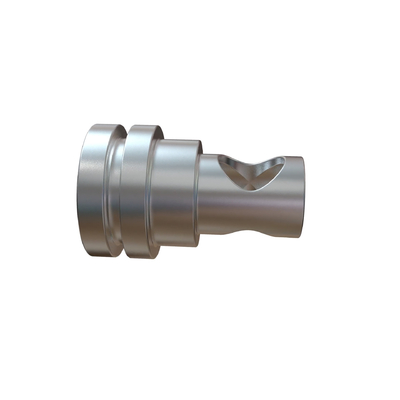

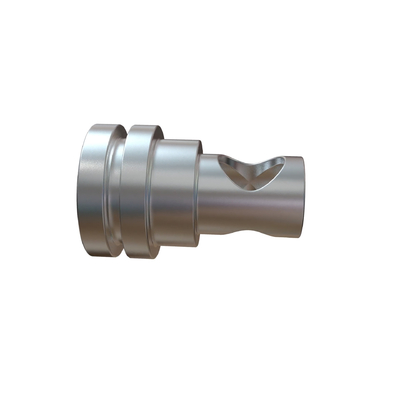

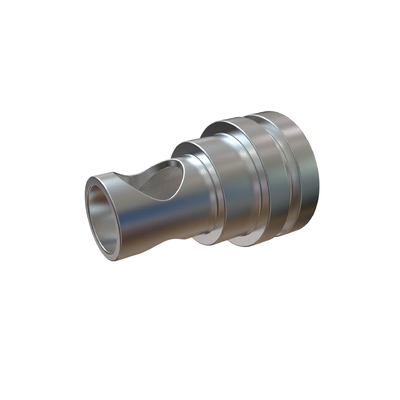

Lost Wax Stainless Steel Casting Pipe Fittings for Auto Parts

|

Product Details:

Payment & Shipping Terms:

|

| Part Name: | Pipe Fittings | Application: | Auto Parts |

|---|---|---|---|

| Material: | Stainless Steel | Technology: | Lost Wax Casting |

| Surface Treatment: | Pickling, Sandblasting And Machining | Service: | OEM |

Lost Wax Stainless Steel Casting Pipe Fittings for Auto Parts

Product Details

![]()

Production Process

![]()

About Us

As a rising star in the industry of precision investment casting, Sunrise has been dedicated to the production, marketing, and R & D of quality precision casting products since its founding. Investment casting, or lost-wax casting, is one of the oldest metal forming process, dating back thousands of years, in which an expendable mold is made around a wax pattern that is to be burned away before molten metal is poured in.

It is a precision casting process used to create metal parts, especially complex, intricate or thin-wall castings from almost any alloy. JYG has been providing high-integrity, close-tolerance, near-net-shape precision casting parts for the customers of various industries around the world and gradually becoming a trusted name in the foundry industry.

Our Service

A lot of senior engineers from our Technical Department provide one stop service including product design, cost calculation, production process, inspection, issued part solution.

Quality always comes first, and we commit ourselves to making superior quality products with most competitive price.

![]()

FAQ

1. Q: How about your quality?

.

2. Q: What is the delivery time & transport time?

3. Q: Could you produce customized products according to your drawing or sample?

Contact Person: Paul

-

Kitchenware Parts Bathroom Hardware 304 316 Stainless Steel Casting Parts Lost Wax Casting

-

Stainless Steel Precision Investment Casting Farm Machinery Parts

-

Precision Investment Casting 304 316 Stainless Steel Lost Wax Casting Pump and Valve Parts

-

Lost Wax Casting 304 316 Stainless Steel Investment Casting Golf Head

-

304 316 Precision Investment Stainless Steel Casting Machinery Parts

-

304 316 Stainless Steel Lost Wax Casting Parts Machine Hardware Parts