|

|

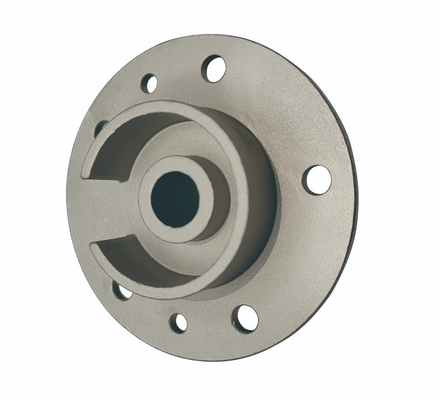

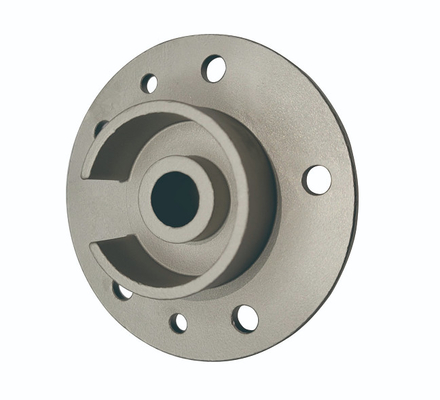

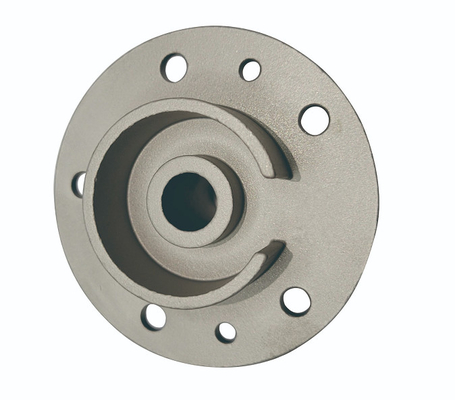

304 316 Stainless Steel Precision Investment Casting Auto Spare Flanges

|

Product Details:

Payment & Shipping Terms:

|

| Material: | Stainless Steel | Item Name: | Flange |

|---|---|---|---|

| Application: | Auto Part | Process: | Precision Casting |

| Finish: | Sandblasting | OEM: | Available |

304 316 Stainless Steel Precision Investment Casting Auto Spare Flanges

Product Details

![]()

Production Process

Silica sol investment casting and water glass are the two primary investment casting methods now days. The main differences are the surface roughness and cost of casting. Water glass method dewaxes into the high-temperature water, and the ceramic mold is made of water glass quartz sand. Silica sol method dewaxes into the flash fire, and silica sol zircon sand makes the ceramic mold. Silica sol method costs more but has the better surface than water glass method.

Advantages:

1. High dimensional accuracy,good surface and quality

2. Better corrosion resistance

3. Less failure rate

![]()

![]()

Factory Introduction

Sunrise Foundry is a professional Metal Foundry, located in Ningbo. We have been producing Gray Iron,

Ductile Iron Castings and and any other precision castings for more than 25 years.

We are dedicated to meet different requirements of various customers across the world, products are mainly

involved Agricultural and Construction Machinery, Hydraulic, Mining industry, Municipal Products, some steel

and stainless steel castings for Pumps and Valves, Pipe Fittings, etc.

Please feel free to contact us if you have any requests.

A. We are able to finish up to 2000 tons raw material every year , generally , one full 20 feet container ( about 20 tons) can be done in 20- 25 days

A. Just in one week for new samples that need to be done in new tools , and we can deliver samples within 24 hours for exsiting samples once received your request .

Q.What are your popular payement menthods ?

A. T/T is our prior choose for all , of course , we are also accept L/C , Westunion , paypall .

Q . Can you provide custom service ?

A . Yes , we provide standard and custom service for all our products.

Contact Person: Paul

-

Kitchenware Parts Bathroom Hardware 304 316 Stainless Steel Casting Parts Lost Wax Casting

-

Stainless Steel Precision Investment Casting Farm Machinery Parts

-

Precision Investment Casting 304 316 Stainless Steel Lost Wax Casting Pump and Valve Parts

-

Lost Wax Casting 304 316 Stainless Steel Investment Casting Golf Head

-

304 316 Precision Investment Stainless Steel Casting Machinery Parts

-

304 316 Stainless Steel Lost Wax Casting Parts Machine Hardware Parts