|

|

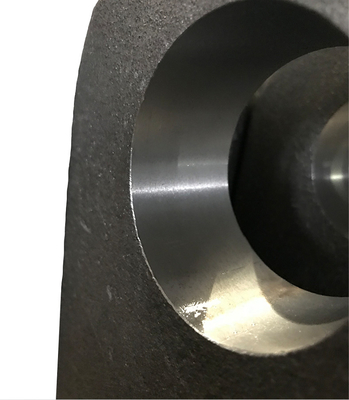

Steel Precision Investment Casting Hydraulic Accessories Hydraulic Cylinder End Caps

|

Product Details:

Payment & Shipping Terms:

|

| Item Name: | Hydraulic Cylinder End Caps | Material: | AISI 1045 |

|---|---|---|---|

| Process: | Precision Casting, Investment Casting | Heat Treatment: | Annealing, Normalizing, Quenching, Tempering |

| Surface: | Machining Or Spay Painting | Weight: | 5kg~10kg |

| Size: | Customized |

Steel Precision Investment Casting Hydraulic Accessories Hydraulic Cylinder End Caps

Product Details

| 1.Material: | Carbon Steel, Alloy Steel, Stainless Steel, Ductile Iron, Gray Iron, High Cr Iron, High Mn Steel |

| 2.Items: | FOB Ningbo or Shanghai, CIF ***, Transoirtation by sea |

| 3.Lead time: | 30-40 days |

| 4.Place of origin: | Ningbo, China |

| 5.Software for specification drawings: | PDF,Auto CAD, Solid Work, JPG, PROE |

| 6.Main production equipments: | Wax injection, CNC-machine, machine-center, heat treatment furnace |

| 7.Productivity: | 50000 pcs/year |

| 8.Packaging: | Wooden package after mandatory treatment or other |

![]()

About Us

Our company is specialized in Custom Cast steel precision casting for many years, we have our own design team who had succeed in developing thousands of kinds of Custom investment casting 1045 carbon steel spare parts in the past 10years, based on our big warehouse, we combine develop, production, quality control, packing and transportation together. We supply our customers a full and comprehensive service and let customer without any concerns.Custom investment casting 1045 carbon steel spare parts are exported to USA, CANADA, ITALY, GERMANY and Japanese. We are expecting your visit and to start our business cooperation.

Production Process

![]()

![]()

Our Capability

We have updated our production line. Our production process include Resin Sand Molding Line, Shell Molding Line, Wet Green Sand Casting and Lost Wax Investment Casting Production Process.

Quality Control

Quality Control is one of the most important process in production. We insist that 100% inspection before shipment and ensure parts without any flaws when sending out.

We have complete quality inspection facilities including mechanical testing, chemical analysis, tensile strength, hardness, spectrometer, ultrasonic testing, etc.

Contact Person: Paul

-

Cast Steel Railroad Accessories and Machine Parts Casting

-

Cast Steel Engine Block for Auto Spare Parts

-

Precision Investmet Casting Steel Bearing Block Seat

-

Precision Steel Investment Casting Construction Machinery Metal Fittings

-

Precision Coal Steam Investment Castings Boiler Parts Air Nozzle Hood Boiler Spare Parts

-

Excavator Precision Investment Steel Casting Track Roller