|

|

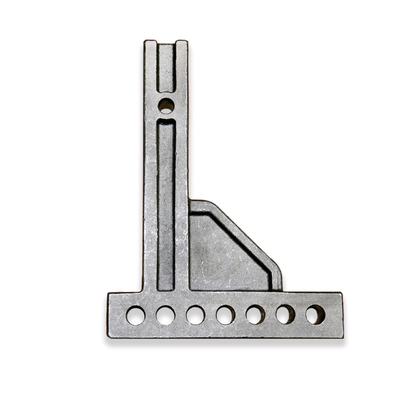

Alloy Steel Precision Lost Wax Casting Agricultural Machinery Spare Parts

|

Product Details:

Payment & Shipping Terms:

|

| Material: | Alloy | Application: | Agricultural Machinery |

|---|---|---|---|

| Process: | Precision Investment Casting | Surface Finish: | Sandblasting |

| Color: | Natural | Size: | As Per Drawing |

| Highlight: | steel investment casting,investment and precision casting,lost wax casting |

||

Alloy Steel Precision Lost Wax Casting Agricultural Machinery Spare Parts

Product Details

![]()

What is Silica Sol Investment Casting?

Silica sol investment casting and water glass are the two primary investment casting methods now days. The main differences are the surface roughness and cost of casting. Water glass method dewaxes into the high-temperature water, and the ceramic mold is made of water glass quartz sand. Silica sol method dewaxes into the flash fire, and silica sol zircon sand makes the ceramic mold. Silica sol method costs more but has the better surface than water glass method.

Advantages:

1. High dimensional accuracy,good surface and quality

2. Better corrosion resistance

3. Less failure rate

Silica Sol Investment Casting production line:

![]()

![]()

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

A: No MOQ for normal products. But for the new design products which need to make the new mould, the MOQ would be up to 100-1000pcs.

A: We can offer free samples for the new idea of regular customers. For new customers,we need sample charge, but we can return the charge once you place any orders. So, basically the samples are free.

A: Generally it is 5-10 days

Contact Person: Paul

-

Precision Investment Casting Fork Pallet Trolley Bracket

-

Precision Investment Lost Wax 42CrMo Steel Casting

-

Cast Steel Railroad Accessories and Machine Parts Casting

-

Cast Steel Engine Block for Auto Spare Parts

-

Precision Investmet Casting Steel Bearing Block Seat

-

Precision Steel Investment Casting Construction Machinery Metal Fittings