|

|

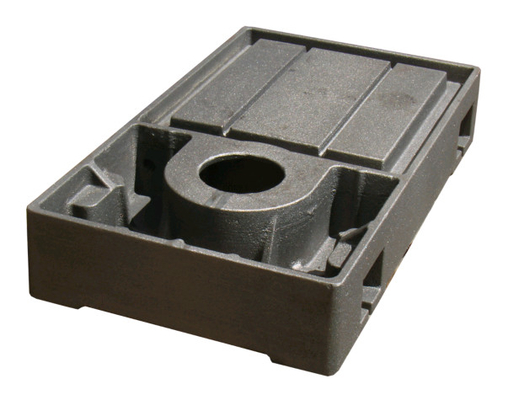

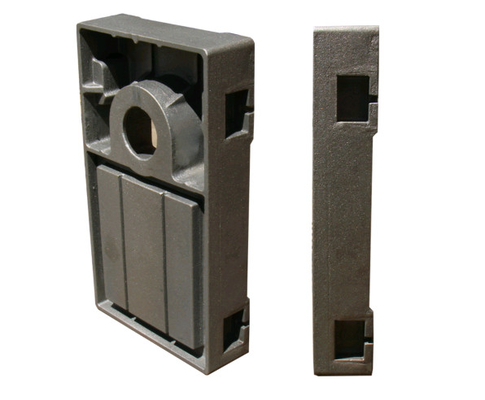

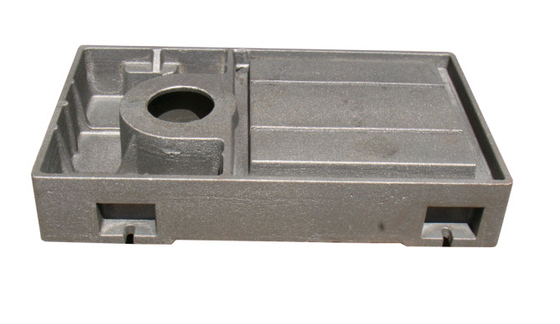

Cnc Machining Grey Cast Iron Casting Parts For Drilling Machinery ASTM Standard

|

Product Details:

Payment & Shipping Terms:

|

| Item Name: | Drilling Machinery Base | Application: | Drilling Machinery |

|---|---|---|---|

| Material: | Grey Iron | Production Process: | Sand Casting+Cnc Machining |

| Surface Treatment: | Painting, Polishing, Powder Coating, Zinc Plating | Weight: | 0.2- 200 Kg |

| Standard: | GB/T9439-2010, | ||

| Highlight: | gray iron casting process,green sand casting,gray cast iron castings |

||

Best Selling Cnc Machining Iron Cast Drilling Machinery Base Casting Parts

Product Detaiils

| Process | Resin sand casting |

| Specification |

1. Material: gray iron HT200-300 2. Standard: ASTM 3. Surface finish: shot blasting, painting, machining,etc. 4. Weight: 100~40000kgs 5. Maximum Size: 10000x8000x5000mm

|

| Production facilities |

1. Casting facility: resin sand production line, Electric furnace, heat treatment furnace, shot blasting room 2. Machining facility: CNC, boring machine, milling machine, lathe, etc. |

| Application | Machine tool body |

| Quality Inspection | spectrometer, tensile test machine, hardness test machine, metallographic microscope. |

![]()

What is Resin Sand Casting?

Resin sand casting process is a kind of casting process by using the resin sand as the molding material.

Resin sand is a kind of mixture of quartz sand and resin. After mixing and burning, the resin sand could become

very hard and solid, so we called it as the hard mold. The iron casting made by resin sand will be usually called

as resin sand casting.

Resin Sand Casting advantages:

1. Dimensional accuracy, clear external outline

2. Smooth surface, good quality

3. Energy saving, labor saving.

Resin Sand Casting production line

![]()

![]()

Our Service

1. Drawing: We will translate your original drawing, make manufacturing procedure plan, offer professional

suggestions on the design if needed.

2. Engineering design software: Solidworks, Auto CAD.

3. Quality control: We have full set of quality control system to guarantee best product quality. Depends on the products,

we make different item testing plan, different manufacturing procedure and provide certified lab mechanical testing.

4. Sample: Samples available.

Contact Person: Paul

-

GG20 FC20 GG25 FC25 Cast Iron Sand Casting Roller Parts

-

GJL200 GJL250 Grey Iron Sand Casting Industry Machinery Part

-

Hot Dip Galvanizing Grey Iron Casting Pole Eye Plate Guy Hook

-

Cast Iron Foundry Sand Casting GJL20 GJL25 GG20 GG25 Flange Cover

-

Grey Cast Iron Shell Mold Casting Pump Casing

-

Grey Cast Iron Shell Casting Valve Plug Fittings