|

|

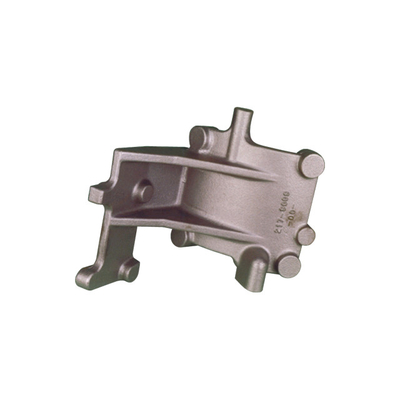

Casting Steel Precision Investment Castings Parts Lost Wax For Engineering

|

Product Details:

Payment & Shipping Terms:

|

| Material: | Cast Steel | Process: | Precision Casting |

|---|---|---|---|

| Application: | Engineering | Quality Control: | 100% Inspected |

| Surface Finish: | Sandblasting | OEM: | Available |

| Highlight: | steel investment casting,investment and precision casting,lost wax casting |

||

Lost Wax Casting Steel Precision Casting Parts for Engineering

Product Details

| Material | Carbon Steel, Low Alloy Steel, Ductile Iron, Gray Iron |

| Standard | DIN, ASTM,JIS etc |

| Certificate | ISO9001:2000 ISO9001:2008 ISO / TS16949 |

| Weight range | 1Kgs-2000Kgs |

| Moulding Process |

Lost Wax Casting Process (Silica Sol Process, Water Glass Process )

Sand Castings ( Resin Sand Casting, Green Sand Casting, Shell Molded Casting, Lost Foam Casting, etc ).

|

| Surface treatment | Painting, Polishing, Heat treatment, etc. |

| Machining | Lathe, CNC(HASS), Drilling Machine, Milling Machine, Boring Machine, Planing Machine |

| Packing | wooden cases, cartons, as customers' requirements. |

| Inspection | Foundry in-house Third party inspection available upon customers' requirement |

![]()

About Us

We are dedicated to meet different requirements of various customers across the world, products are mainly

involved Agricultural and Construction Machinery, Hydraulic, Mining industry, Municipal Products, some steel

and stainless steel castings for Pumps and Valves, Pipe Fittings, etc.

Production Process

![]()

Our Services

1. Rich experience in ODM and OEM.

2. Excellent One-stop service.

3. High Quality Precision Customized forging & Casting services.

4. The lowest price.

5. Strict quality control.

6. We can manufacture it according to customers requirements.

Quality Control

Quality Control is one of the most important process in production. We insist that 100% inspection before

shipment and ensure parts without any flaws when sending out.

We have complete quality inspection facilities including mechanical testing, chemical analysis, tensile strength,

hardness, spectrometer, ultrasonic testing, etc.

1. How to get a quotation?

Please send us drawings in igs, dwg, step etc. together with detailed PDF.

If you have any requirements, please note, and we could provide professional advice for your reference.

2. What if we do not have drawing?

Samples would be available, and we would send you drawing to confirm.

Of course, we would ensure the safety of the drawing.

3. How to pay?

For small quantity, we could provide Paypal, Paypal commission will be added to the order.

For the big one, T/T is preferred.

Contact Person: Paul

-

Cast Steel Railroad Accessories and Machine Parts Casting

-

Cast Steel Engine Block for Auto Spare Parts

-

Precision Investmet Casting Steel Bearing Block Seat

-

Precision Steel Investment Casting Construction Machinery Metal Fittings

-

Precision Coal Steam Investment Castings Boiler Parts Air Nozzle Hood Boiler Spare Parts

-

Excavator Precision Investment Steel Casting Track Roller