|

|

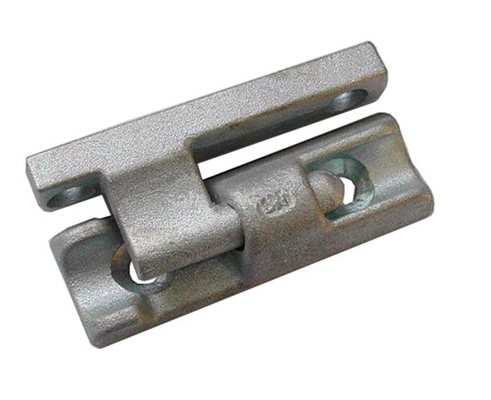

Alloy Steel Precision Investment Castings Automotive Accessories Door Hinge Spare Parts

|

Product Details:

Payment & Shipping Terms:

|

| Application: | Industrial Machine | Material: | Alloy Steel |

|---|---|---|---|

| Process: | Investment Casting | Surface Treatment: | Polish, Coating , PVD , Sand Blast And Etc |

| Dimensions: | Customized | OEM: | Available |

| Highlight: | steel investment casting,investment and precision casting |

||

Alloy Steel Investment Casting Automotive Accessories Steel Door Hinge Spare Parts

Description

Investment casting is an industrial process based on and also called lost-wax casting, one of the oldest known metal-forming techniques.From 5,000 years ago, when beeswax formed the pattern, to today’s high-technology waxes, refractory materials and specialist alloys, the castings allow the production of components with accuracy, repeatability, versatility and integrity in a variety of metals and high-performance alloys.

The process is generally used for small castings. It is generally more expensive per unit than die casting or sand casting, but has lower equipment costs. It can produce complicated shapes that would be difficult or impossible with die casting, yet like that process, it requires little surface finishing and only minor machining.

Investment casting is used in the aerospace and power generation industries to produce turbine blades with complex shapes or cooling systems.Blades produced by investment casting can include single-crystal (SX), directionally solidified (DS), or conventional equiaxed blades. Investment casting is also widely used by firearms manufacturers to fabricate firearm receivers, triggers, hammers, and other precision parts at low cost. Other industries that use standard investment-cast parts include military, medical, commercial and automotive.

Product Details

| Process | Investment casting/lost wax casting,sodium silicate or silica sol process. |

| Specification |

1.Material:steel,alloy steel,stainless steel. 2.Standard: ASTMDINBSJISGB. 3.Surface finish: shot blasting,sand blasting, polishing, acid clean-up,machining,painting,etc. 4.Weight: 0.1-90kg.

|

| Production facility |

1.Casting facility: wax injector,moulding line,electric furnace,heat treatment furnace,shot-blasting machine, sand-blasting machine.

2.Machining facility: CNC, NC lathe,ordinary machine tools,polishing machine. |

| Heat treatment | Annealing/Tempering/Normalizing/Quenching/Solution treatment. |

| Test facility | spectrometer, tensile test machine, hardness test machine,impact tester,CMM,UT,MT,PT test facility. |

![]()

![]()

1.Your inquiry related to our product & price will be replied within 24hours.(E-mail or TradeManger)

2.Well-trained & experienced staff are to answer all your inquiries in English.

3.Working time: 8:30am – 5:30pm, Monday to Friday (UTC+8).

4.Your business relationship with us will be confidential to any third party.

5.Good after-sale service offered, please get back if you got question.

6.Welcome to our company.

-- Please send us your 2D/3D drawings for a quick quotation.

-- The file format is PDF / STP / STEP / IGS / DWG and etc.

-- IF there are no drawings, we can make the drawings according to your samples!

How soon can I get a sample?

-- In 3 weeks according to the sample structure .

What is your MOQ?

-- MOQ depends on the product structure, we welcome trial order before mass-production.

-- Rapid PROTOTYPING service is available for your sample of casting!

How long is your delivery time?

-- It depends on the product dimension, technical requirements and quantity. We always try to meet customers' requirement by adjusting our workshop schedule.

Contact Person: Paul

-

Cast Steel Railroad Accessories and Machine Parts Casting

-

Cast Steel Engine Block for Auto Spare Parts

-

Precision Investmet Casting Steel Bearing Block Seat

-

Precision Steel Investment Casting Construction Machinery Metal Fittings

-

Precision Coal Steam Investment Castings Boiler Parts Air Nozzle Hood Boiler Spare Parts

-

Excavator Precision Investment Steel Casting Track Roller