|

|

Sales & Support

Request A Quote - Email

Select Language

|

|

|

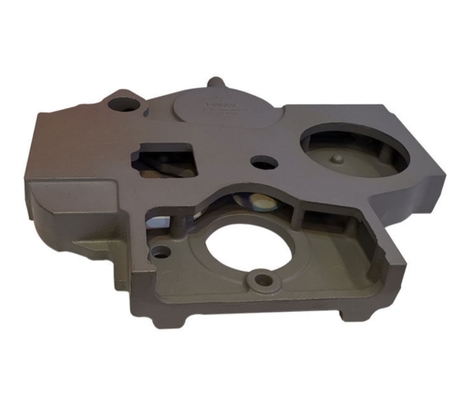

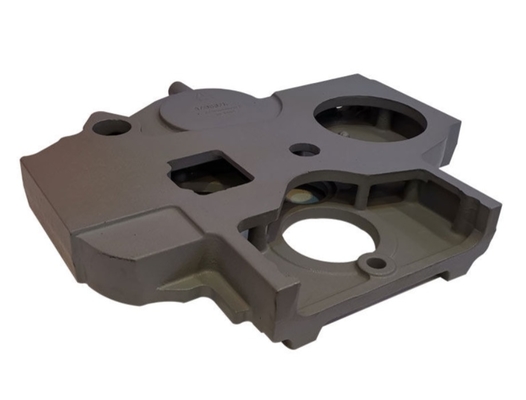

EN-GJL-250 Grey Iron Sand Casting Spare Parts Iron Casting Parts

|

Product Details:

Payment & Shipping Terms:

|

| Material: | Grey Iron | Process: | Iron Sand Casting |

|---|---|---|---|

| Application: | Machinery Part | Size: | As Per Drawing |

| Finish: | Sandblasting | OEM: | Available |

EN-GJL-250 Grey Iron Sand Casting Spare Parts Iron Casting Parts

Product Details

Production Process

![]()

About Us

We can undertake the production and machining of cast iron and cast steel parts made from various materials according to customer requirements, including ductile iron, gray iron, carbon steel, stainless steel, heat-resistant steel, high manganese steel, medium chromium wear-resistant steel, and wear-resistant low-alloy steel. Our products are widely used in automobiles, mining, construction machinery, various water supply equipment, and other fields. Our factory has an annual production capacity of over 10,000 tons of cast steel, cast iron, and ductile iron. Our products are sold to more than 20 countries, including Germany, the United States, South Korea, and Japan.

Quality Control

![]()

FAQ

A:1.We need the drawings for quote.

2.You accept the quotation and sign the contact, pay the mould cost, we will arrange to make samples for approval.

3.You approve the samples and pay the advance.

4.We arrange to manufacture and ship to you.

5.Pay balance.

6.Received the products and feedback.

Contact Person: Paul

-

GG20 GG25 GJL20 GJL25 Cast Grey Iron Casting Flange Cover

-

EN-GJS-250 Grey Cast Iron Machine Tool Bed

-

Gray Cast Iron Spools and Valve Pipe Fittings

-

Metal Foundry Grey Cast Iron Parts Machinery Oil Pump Parts

-

Gray Cast Iron Deep Wheel Agricultural Machinery Casting Parts

-

Lost Foam Casting Grey Cast Iron Parts Machinery Parts